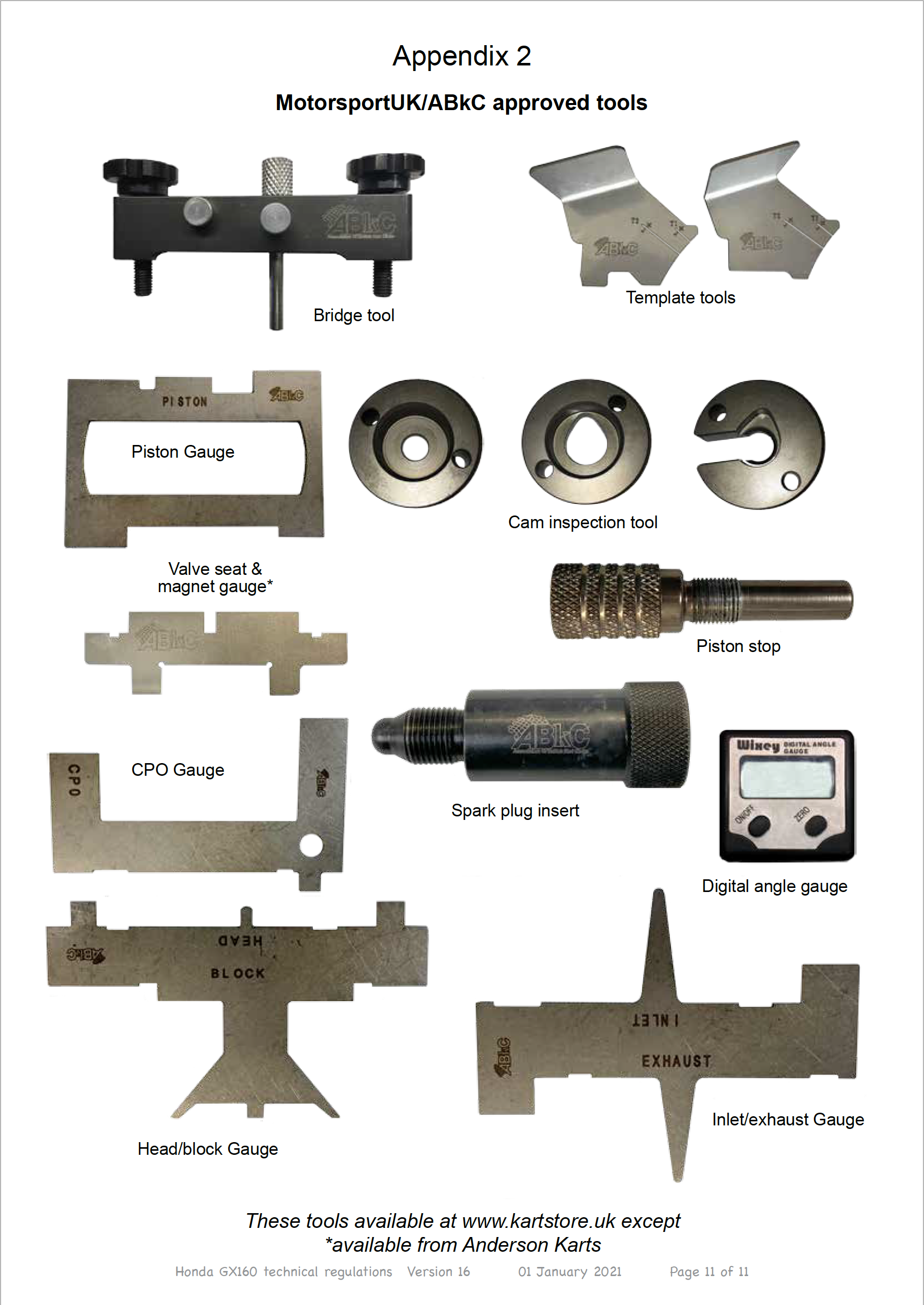

Part 11 - Inspection tools

23. Crankcase

The crankcase can only be modified by the removal of the governor mechanism and in all other respects must be standard and unmodified. If completely removed, the hole in the crankcase must be  to prevent oil leakage (unless a suitable pulse take-off is used in its place). The crankcase bearings and seals must be standard and unmodified.The bore must be standard only, service limit 68.165mm at all points of the bore. No sleeving or surface material change to the cylinder bore is allowed but honing is permitted. The cylinder mating face may be machined to achieve a minimum deck height of 44.9mm (read between the cylinder mating face and the cast face of the piston, in line with the piston pin, with the piston at BDC). The ABkC block tool may be used to check this dimension. (See drawing 2 & 3 in Appendix 1).

to prevent oil leakage (unless a suitable pulse take-off is used in its place). The crankcase bearings and seals must be standard and unmodified.The bore must be standard only, service limit 68.165mm at all points of the bore. No sleeving or surface material change to the cylinder bore is allowed but honing is permitted. The cylinder mating face may be machined to achieve a minimum deck height of 44.9mm (read between the cylinder mating face and the cast face of the piston, in line with the piston pin, with the piston at BDC). The ABkC block tool may be used to check this dimension. (See drawing 2 & 3 in Appendix 1).

When measuring a K type engine, 1.3mm should be added to the obtained reading, to accommodate the dish in the piston. Welded repairs are allowed to the engine mounting area at the crankcase base and additionally to one (only) of the ignition coil mounting posts, provided that this does not change the position or thread size of the post. No other welded repairs are permitted.

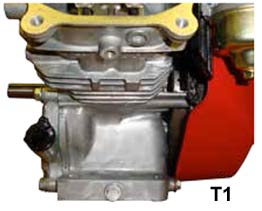

24.Crankcase side cover

Must be standard and unmodified and positioned with both standard and unmodified dowels in place. T1 and T2 side covers are interchangeable.